Ethanol Conversion Preparation Services

The migration to ethanol-based fuel is spreading rapidly across the country. Some regions of the United States have already converted and others are on aggressive timetables to do so. Retailers and commercial operators large and small are beginning to face the realization that ethanol-blended fuel is on the way and they need to be prepared or they could face dire consequences.

The migration to ethanol-based fuel is spreading rapidly across the country. Some regions of the United States have already converted and others are on aggressive timetables to do so. Retailers and commercial operators large and small are beginning to face the realization that ethanol-blended fuel is on the way and they need to be prepared or they could face dire consequences.

Converting to Ethanol-blended Fuels |

||||||||||||||

The migration to ethanol-based fuel is spreading rapidly across the country. Some regions of the United States have already converted and others are on aggressive timetables to do so. Retailers and commercial operators large and small are beginning to face the realization that ethanol-blended fuel is on the way and they need to be prepared or they could face dire consequences.

Regulatory and widely-accepted industry standards require that a storage tank receiving ethanol-blended fuels must be free of all water, debris and accumulated sodium salts before introduction of the fuel. According to industry experts, the presence of these constituents in ethanol-blended fuel poses serious consequences for retailers and their customers – they are simply not compatible with ethanol. |

||||||||||||||

What Happens when Ethanol-blended Fuel is Added to a Storage Tank: |

||||||||||||||

|

||||||||||||||

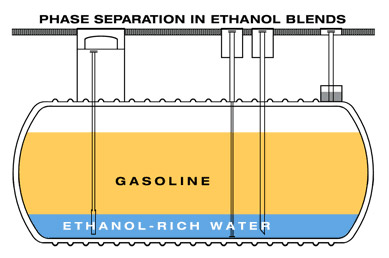

The introduction of ethanol to gasoline storage tanks brings with it some significant concerns to the operator. The first and largest concern is water – ethanol and water simply are not compatible. It takes a small amount of water to cause what is known as “phase separation” in a tank. Therefore, it is critical that ethanol-blended gasoline is not exposed to water at any time. That’s why ethanol-oxygenated gasoline is not typically transported in pipelines, which frequently contain water. Instead, the ethanol is generally added to tanker trucks at the terminal, immediately before delivery. When water does contaminate ethanol-blended gasoline, the water dissolves into the ethanol and disperses throughout the tank. Once it exceeds its maximum tolerance, the alcohol/water mixture will separate from the gasoline. Depending upon the actual conditions, up to 80 percent of the ethanol will separate from the gasoline, forming two separate layers in the tank: Gasoline on top of ethanol-rich water. The gasoline layer, because it has been stripped of most of the ethanol, will be lower in octane and most likely out of specification. The bottom layer, which is a mix of ethanol and water, simply won’t burn. Debris or particulates, and accumulated sodium salts create similar problems in tanks containing ethanol-blended fuels. For this reason, it is critical that all tanks receiving ethanol fuels should be carefully inspected prior to the first introduction of the fuel to ensure that there is no water, debris or accumulated sodium salts. |

||||||||||||||

The types of problems that occur when water or debris contaminates ethanol-blended fuels include: |

||||||||||||||

|

||||||||||||||

Can't You Just Remove the Water and Proceed? |

||||||||||||||

More than half of the USTs we inspect prior to the introduction of ethanol-blended fuels require some level of preparation services in order to avoid some or all of the above problems. It is a fact that all gasoline tanks contain some level of water. That water must be removed before the introduction of ethanol-blended fuel. Many operators rely upon their Automatic Tank Gauge (ATG) or their dipstick and water-detecting paste to tell them whether they have water, then pump it out until these devices tell them that no water remains. This is a mistake. These tools are not sophisticated enough to ensure that there is no water in the tank, the condition necessary before introducing ethanol. In fact, conventional water-finder paste and water detection filters will not detect a phase-separated bottom layer of a tank quickly enough to react to it before problems occur. In our experience, more than half the time, unlevel tanks result in water collecting in an area of the tank that is not detected by the tank gauge or dipstick. There is no way to know that from above ground with a conventional water-detecting device. |

||||||||||||||

Tanknology is the Nation’s Leader in Ethanol Conversion Inspection and Preparation Services |

||||||||||||||

Working with major oil companies and regulatory officials throughout the country, Tanknology has developed specific protocols for tank inspection and ethanol preparation services. We have performed these services on thousands of tanks, all across the country. In many cases, we have adapted our protocols to the needs of specific customers and their unique requirements. In most cases, we can perform tank inspection and ethanol conversion preparation services in a matter of hours – without taking your site out of operation. Because Tanknology is the nation’s largest provider of UST compliance solutions, we have the capacity to react to customer needs in every corner of the country. You can rely on Tanknology to ensure that your fuel tanks are in optimum condition for that first delivery of ethanol-blended fuels. |

||||||||||||||

Additional Resources |

||||||||||||||

For more information about ethanol and converting your site to ethanol-blended fuel, here are some links to third-party sites that you may find helpful: |

||||||||||||||